Ultra High Molecular weight Polyethylene, often referred to as UHMWPE, is a high-performance polymer that is famous because of its high durability, wear resistance and its stability in terms of chemical stability. These materials have resulted in the use of the material in many industries, ranging from heavy machinery production to advanced medical equipment. Its special lightweight strength, low friction and impact resistance enable engineers and designers to come up with products that are capable of enduring extreme conditions without compromising on efficiency and reliability. The diversity of the uhmwpe plastic application points to its versatility as well as the vitality of the product in modern technology.

UHMWPE in Industrial Machinery

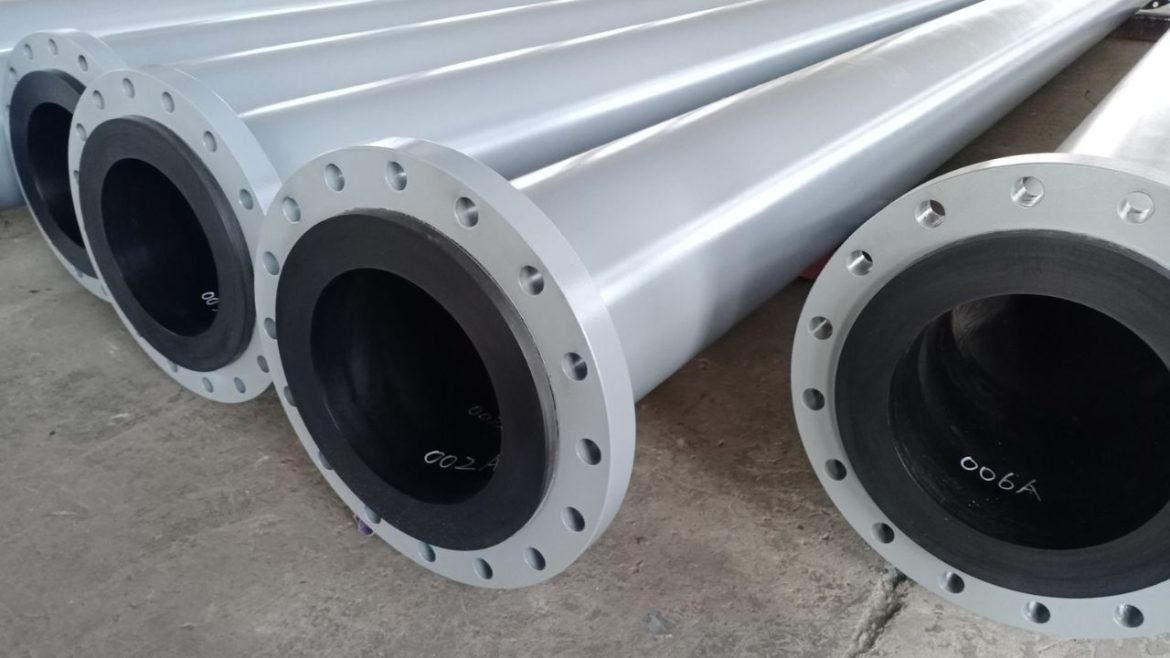

The use of UHMWPE in machinery in industries is one of the most frequent cases of use where its components are subjected to constant friction and wear. Conveyor belts, chutes, and wear strips, as well as guide rails, are made of UHMWPE sheets, blocks, and pipes. The low coefficient of friction causes less resistance and less energy usage in the movement of moving parts, and also the high abrasion resistance of the material increases the life of critical parts. Industries like mining, manufacturing and material handling can better enhance the efficiency of their operations, reduce downtime and costs in terms of maintenance with the aid of UHMWPE. Its chemical resilience also makes it such that the equipment that is exposed to rough materials will still last longer before it becomes useless.

Food and Beverage Industry

The non-toxic characteristics of UHMWPE result in its suitability for food processing equipment. Cutting boards, liners and conveyor surfaces are manufactured using sheets and blocks, which minimize the sticking of the product and make it easy to handle. The waterproof and cleaning agent-resistant material guarantee a high level of hygiene and the strict rules of safety. These properties have enabled UHMWPE to emerge as a very potent option in the contexts where durability, sanitation, and uniform performance are of utmost importance.

UHMWPE in Medical Devices

UHMWPE has been a necessary material in the medical field for the use of prosthetics and joint replacement. It has superior wear resistance, which has resulted in long-lasting hip and knee implants that minimize friction and wear in the human body. The biocompatibility of the polymer makes it not react with tissues, as well, whereas its strength-to-weight ratio helps to meet the durability needed by the polymer in load-bearing. In addition to orthopedics, UHMWPE is applied in the surgical devices and parts where the reliability, minimal friction, and insensitivity to the sterilization procedures are imperative. The healthcare uses illustrate how the material can be used to achieve extremely sophisticated and rigorous performance.

Sports and Recreation Uses

Other applications of UHMWPE are in sports and recreational equipment because of its lightweight but durable qualities. Sleds, protective gear, skateboards and ropes also have the advantage of being impact and abrasion-resistant without the unjustified weight. UHMWPE fibers have been implemented in vests and helmets used in ballistic protection due to their high tensile strength and flexibility, which enables one to be safe and move freely. The toughness and low density of UHMWPE allow it to be used in high-performance recreational and protective equipment.

Marine and Fiber Applications

Other than industrial, medical, and recreational applications, UHMWPE is extremely essential in the marine environment. Its anti-corrosion and water absorption characteristics make it appropriate for ropes, fishing lines and boat parts. UHMWPE fibers are characterized by high strength and are not heavy, and this is critical in areas where durability and flexibility are needed. Fibers are also applied in safety and defense, which proves the versatility of the material in various operational situations.

Conclusion

The outstanding nature of the UHMWPE in terms of properties, such as wear resistance, impact strengths, chemical stability and low friction, has rendered it an indispensable material in various industries. From the dawn of time, with heavy industrial machinery and hygienic food processing equipment to life-saving medical equipment and high-performance recreational equipment, UHMWPE has always been a reliable and efficient player. It has multiple levels of flexibility that enable it to keep up with the changes in technology so that it can still fulfill the ever-evolving and demanding needs of modern-day engineering and design. With the industries still in pursuit of materials that offer a compromise between strengths, toughness and functionality, UHMWPE has become an essential ingredient and has demonstrated itself useful in both the factory floor and human body.