No matter how skilled you are, there are always tricky components to machine. CNC machining and other production line processes take a significant amount of time and money.

Production line processes can become inefficient when not enough time is allotted for the machining process. Overtime will cost you money, and the quality of the products may not be the same as it was when you started.

With Custom CNC Machines, you get an affordable and flexible solution for all your CNC needs. Their wide range of equipment provides solutions for large and small jobs, allowing you to pick an option that suits your size and budget.

Let’s discuss a significant tooling system of custom CNC machining called 5-axis.

5-Axis CNC Machining SYstem

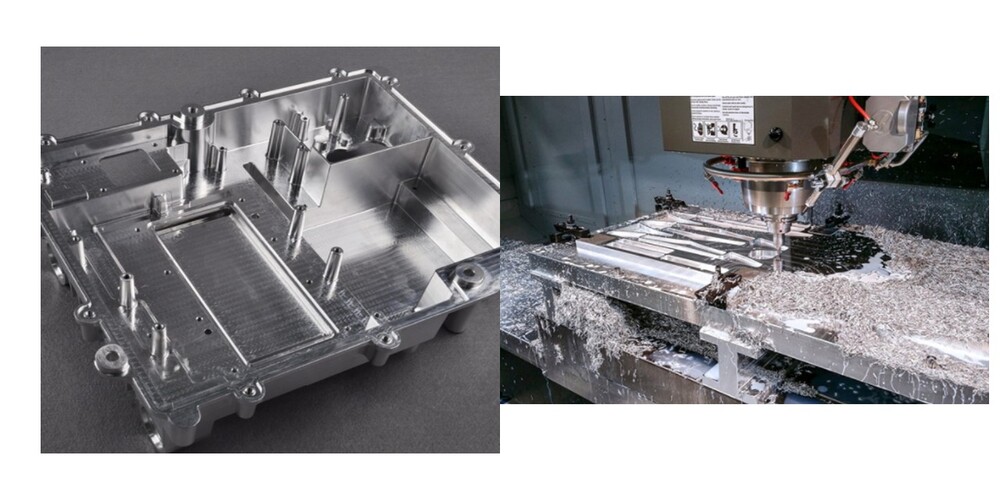

5-Axis CNC machining system can produce complex shapes that are difficult to manufacture with traditional manufacturing methods. It makes it possible to produce more uniform parts with less waste and less time than before.

Typically, the term “5-Axis” is used to describe the full range of simultaneous movement found in a 5-axis machine, including pitch (X), roll (Y), and yaw (Z).

This includes movement about a fourth rotary axis (Cr). The workpiece can move simultaneously in all four spatial directions within a single setup.

Benefits Of 5-Axis CNC Machining SYstem

There are several benefits of this machining system, but we will discuss some highlighted ones.

1. Enhance Cutting Conditions

5-Axis CNC machining is a process that gives the manufacturer the ability to create parts with precisely placed features and threads that could not be produced on other conventional machines. The enhanced cutting conditions created by 5-Axis CNC machining allow parts to be produced with high-quality finishes, tight tolerance, and less rework.

With a 5-axis machining center, you can remove metal better than ever and create better surfaces.

The ability to machine complex forms, interior features, and undercuts is one of the most significant benefits of this technology. With such flexibility, it is possible to achieve a higher degree of accuracy and reduce part costs via mass production.

2. Boost Production Time With Reduction In Processing Time

CNC machining services are constantly growing as a popular method of giving your company the ability to produce parts with a high-quality finish. The cost-efficient nature of 5-axis beam machining systems makes them a significant investment.

Unlike 3-axis systems, a 5-Axis CNC Machining system can process multiple sides of the material simultaneously. With this, the processing time is reduced, and production time increases.

3. Maximum Accuracy

With a 5-Axis CNC Machining system, you can create 3D parts that could not be made using traditional machines. By rotating the part 360 degrees and making multiple passes on each part, a 5-axis machine allows for maximum accuracy in the machining process.

The high-speed, highly rigid table allows you to perform milling, drilling, and boring operations faster than a conventional machine. It is advantageous during mold, tool, and die work where time is of the essence.

With the 4th and 5th axis, you can produce complex components with complex geometries and accurate shapes that would not be possible with a conventional machining center.