Heroes sometimes need heroes, and they need someone to assure them that it will be alright constantly. Remember that they are human with emotions and feelings, and the fact the world is ‘looking up to them’ does not make it any simpler today. Even you are a hero, and if you look closely, you get to realize that there is so much power within you to make this world a better place for everyone. Even heroes get tired! And it is ok to take a breather whenever you feel like you need to.

What about investments? Are they heroes? If you are confused, the investment we are talking about here is the metal investment casting. We are not talking about money today. What is this investment casting anyway? Investment casting is the process of forming metal that involves using a wax pattern surrounded by a ceramic shell to form a ceramic mold. It refers to the ceramics formed around the wax patterns to create a casing for pouring molten metal.

Procedure and Key Components of Investment Casting

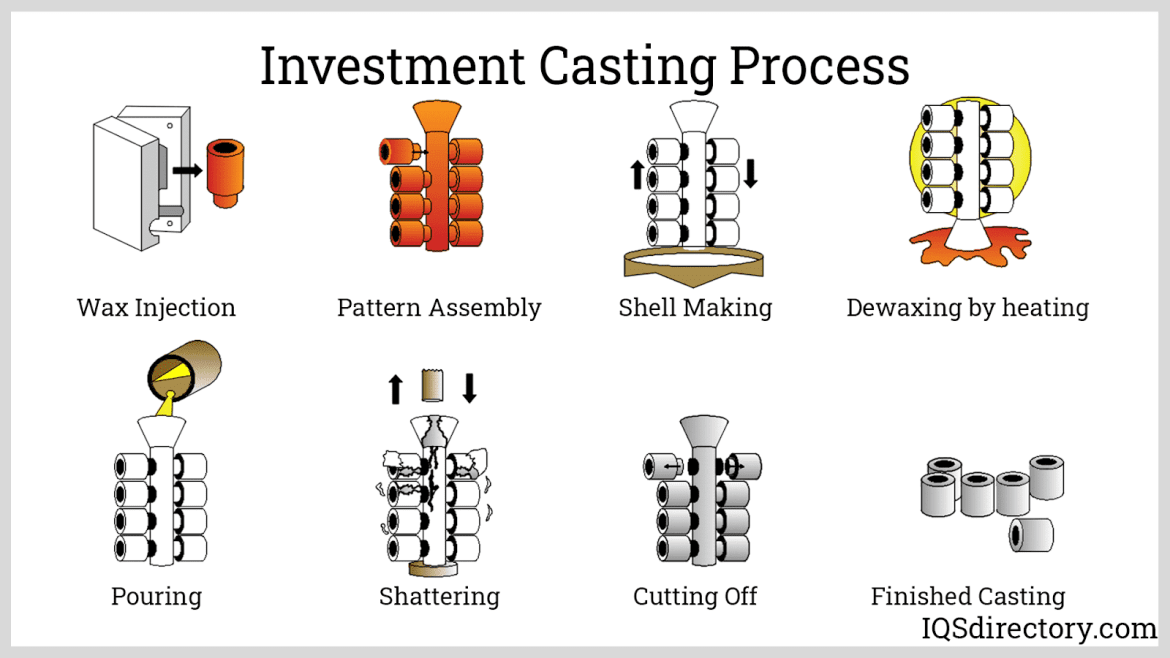

The process includes several specific steps used to design and create the desired pieces. Listed below are some of the steps that involve investment casting:

Step 1: Toolmaking

This is the first and most basic investment casting step that helps achieve precision products. The tools are the wax-injection dies used to create a wax pattern necessary for the second step.

Step 2: Creating the pattern

This step involves creating the pattern or die of the desired workpiece whereby the pattern is made from wax. The wax gets injected into the wax-injection die, and this process is repeated as many times as necessary to produce the number of patterns required to meet order demand.

Step 3: Assemble the wax pattern

Assemble the wax pattern to form a tree-like shape that increases the efficiency of the investment casting process. The assembles allow multiple patterns to go through the rest of the steps together.

Note that the trees that are assembled should be of adequate size.

Step 4: Moulding the Shell

After the trees are assembled, the next step would be to add the shelled casting around it by dipping the tree into a ceramic slurry. Next, it is dipped into fine sand, and this is done repeatedly until the mold formed is thick enough to handle the casting process.

Step 5: Removing the wax

The wax patterns are removed first before the desired material can be poured into the newly shelled mold. This process is achieved by heating the wax inside an oven or steaming the wax.

The removed wax is channeled out and is used to recreate new patterns.

Step 6: Now the casting begins!

Molten metal is poured into the casting after the wax is removed, and there are open spaces inside the casting that are shelled shaped like formal wax patterns.

The poured material remains in the casting until it is fully cooled.

Step 7: Clean the casting

In this step, you can use a hammer to remove the shelled casting until you have the original tree.

Step 8: It’s a wrap!

The last step is to use the desired finishing method on the pieces. Inspections are done on each piece, and any rejects are discarded, and the material is recycled.

Benefits of Investment Casting

- Versatility and flexibility in design

Investing in casting offers freedom of design as it has wide adaptability and does not have limitations when it comes to thickness, shape complexity, and casting size.

Complex passageways and thin-wall sections can be easily cast as investment casting offer exceptional flexibility.

- Material Variety

There is variety when it comes to the different alloys that may be used for investment casting; these are stainless steel, carbon alloy, heat resistant alloy, copper alloy, and many other varieties.

For this reason, investment casting is the most preferred method of metal forming for most project designers in sectors like oil, gas, and medical.

- Variety in applications

Most metal alloys are used in investment castings, such as steel, copper, bronze, nickel, and aluminum. Therefore, investment casting can be used in a wide range of industries to produce many different components.

- Extraordinary surface finish

Unlike sand casting and other casting processes, investment casting gives a very smooth finish that reduces the time and cost incurred in secondary machining. The tolerances of investment castings are also more precise as compared to other casting methods.

Precise Cast offers the most professional casting processes at unbeatable costs. With high efficiency and just-in-time production and delivery that guarantees you top-quality castings. Are you in need of a casting solution and technical support? Contact them today and get your fix!